Founded on a culture of food safety, MMI achieved a Food Safety Audit Score of 99 in 2013. Our Total Quality Management team’s product-consistency validation ensures a continued analysis of our plant’s capabilities and efficiencies – including our expansion, which will encompass more state-of-the-art equipment and automation.

Production Process

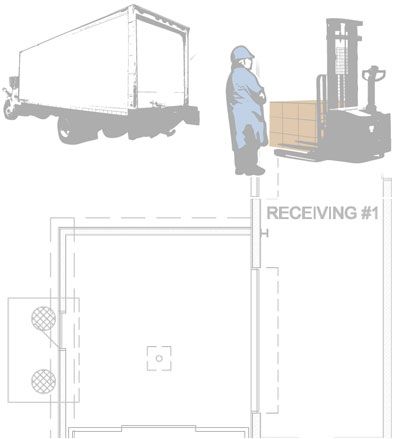

Receiving

- Inventory is taken and ingredients are separated into either dry, frozen or refrigerated storage

Raw ingredients are received and thoroughly inspected

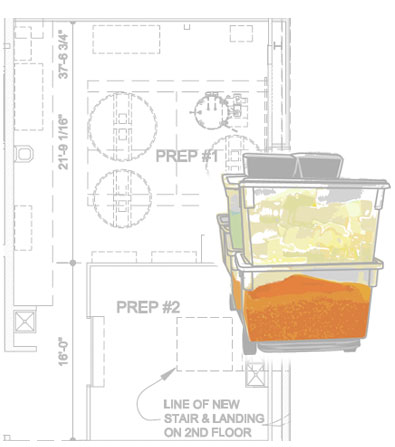

Prep

- Each recipe is staged with ingredients needed and placed back into proper storage location

Individual ingredients are physically examined and only the highest-quality are retained

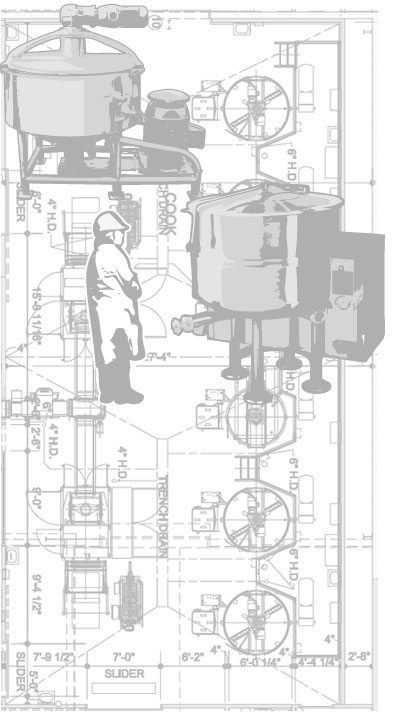

Cooking

- Ingredients are automatically loaded into the kettles in stages, based on our proprietary layer-cooking technique

- The kettles are monitored both in person and electronically to ensure every step is followed correctly

The Kettles are automatically flushed to clean after each recipe cooked

Packaging

- Finished product is sealed into 2, 4 or 8 pound bags and weighed for gross weight accuracy

Next, the product is placed under an X-ray machine to ensure there are no unwanted particles or leaks

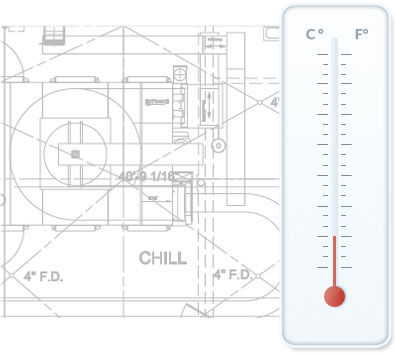

Chilling/Freezing

- The product is pumped at 180 degrees

Then enters the chiller and cooled to below 40 degrees

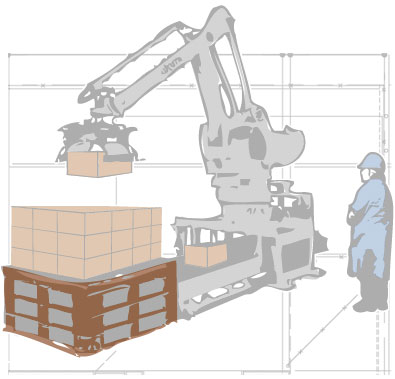

Palletizing/Shipping

- The bags are then placed into master cases which are then auto-palletized

The pallets go to the freezer/refrigerator and are ready for shipping

Contact us if you would like to schedule a tour of our plant.